During an inspection in May 2021, Stefan Burtscher found that the tensioning heads of a suspended facade, which were difficult to access, were heavily corroded (Fig. 1).

During the course of the investigation, it became apparent that the vertical tension heads had never been properly protected against corrosion and that the environmental conditions were “ideal” for corrosion. One stressing cable was not grouted to the top anchor plate and the cavity below was even connected to the outside air through the unfilled grout port (see 2mm diameter endoscope video).

To ensure the safety of the entire structure, we simulated the failure behavior, determined limit values, and created a monitoring concept as part of an expert report.

Since things had to be done quickly at that time, our self-sufficient, easy-to-use, and reliable monitoring system was ideal. During the entire refurbishment, the monitoring system automatically monitored the safety of the structure and informed about current incidents.

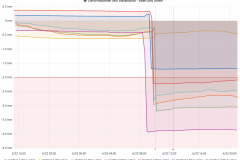

A few days ago, it was possible to transfer the forces to the replacement structure (lift and place underneath) and relieve the tendons. The extent of the unloading and the resulting deformations can be read on the dashboard (Fig. 2).

In the following weeks, we will continue the measurements in order to be able to detect any settlements in time.

We are pleased to have been able to support this challenging project with our innovative monitoring system and look forward to a successful conclusion.