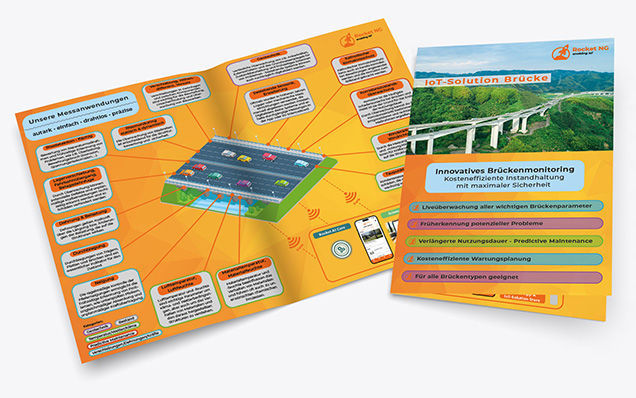

Innovative bridge monitoring

Cost-efficient maintenance

with maximum safety

The importance of bridges for efficient and safe transport and for the economic development of regions is essential. Failures have serious consequences and closures for maintenance must be minimised. With the measurement applications of our IoT Solution Bridge, assessments and decisions can be made on an objective, data-based basis. This ensures a particularly high level of availability and safety, as well as extending the service life and reducing costs.

- Real-time monitoring of all important bridge parameters

- Early detection of potential problems

- Extended service life through predictive maintenance

- Cost-efficient maintenance planning

- Suitable for all bridge types

Our measurement applications

Displacements, Height

Difference, Offset

Displacements in expansion joints and between components are important for the assessment, determination of problems and monitoring of structures.

Static & Dynamic

Crack Monitoring

Monitoring crack widths is crucial for structural assesment and safety.

Crack Detection - Surface

Evaluation of repair measures and early detection of problems such as overloading, reinforcement failure (corrosion, stress corrosion cracking).

Bearing Displacements,

Expansion Joints,

Under Pavement Joints

By monitoring, potential defects and unplanned forces can be detected early and damage can be prevented.

Strain & Load

Strains provide information about the elongation or changes in the load acting on the structures.

Deflection

Deflections of beams, slabs and bridges are a key indicator of their condition.

Inclination

Regular monitoring of the pier inclinations enables early detection of problems such as undermined piers, uneven subsidence and unplanned force transmissions.

Air Temperature,

Humidity

Air temperature and humidity are important parameters for understanding climate and weather conditions, but also for understanding the behaviour of materials and the structures made from them.

Material Temperature,

Material Moisture

Material temperature and moisture influence the behaviour of materials and often lead to undesirable chemical processes.

Dew Point Monitoring

Condensation leads to moisture damage, which can be prevented by dew point monitoring.

Wind Force,

Wind Direction

By measuring wind strength and direction, factors influencing forces and vibrations on the structure can be recognised.

Corrosion Condition Monitoring

Corrosion is the most common cause of damage in reinforced concrete structures and is usually the reason for the end of their lifetime. By monitoring, you can determine and predict the onset of corrosion and take timely action.

Cathodic Corrosion Protection

Cathodic corrosion protection can be applied to already corroded reinforcement and corrosion can be stopped.

Geotechnics

Reliable monitoring of, e.g. anchor forces, extensometers and the groundwater level for condition assessment and early detection of problems - existing systems can also be digitalised.

Existing Sensors,

Extensions

In previous years, loggers or mechanical measuring devices that were often used had to be read manually. Digitalise your systems and collect actual measurements in the app or in the ScienceBoard.

Explore, configure and order this IoT solution with LIVE data in the Rocket App!